Understanding Tube Bundles: Function, Design, and Industry Applications

Tube bundles are critical components in various industrial processes, especially in heat exchangers, cooling systems, and condensers. Their design and functionality are pivotal in ensuring efficient heat transfer and overall system performance. This guide explores the essentials of tube bundles, their functions, design considerations, and how they serve different industries.

What is a Tube Bundle?

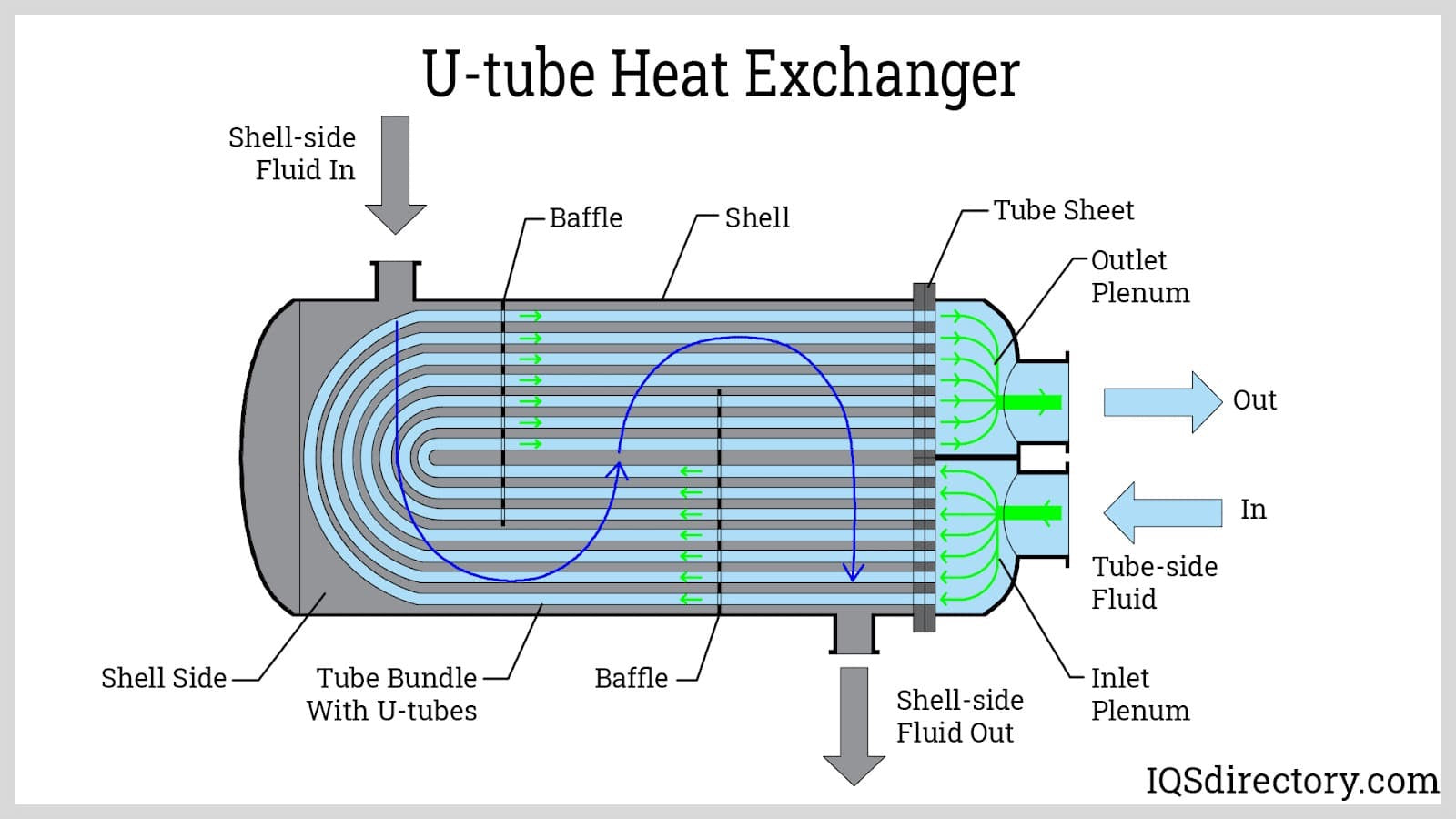

A tube bundle is a collection of tubes arranged within a shell to facilitate heat exchange between two fluids. The fundamental components of a tube bundle include:

-

Tubes: The primary elements where heat transfer occurs. They can be arranged in various configurations, such as straight, U-shaped, or helically wound, depending on the application.

-

Shell: The outer casing that contains the tube bundle. The shell directs the flow of the secondary fluid around the tubes.

-

Tube Sheet: The plates that hold the tubes in place, allowing them to be securely positioned and preventing leakage.

-

Baffles: These are internal structures that guide the flow of the shell-side fluid and enhance heat transfer efficiency by creating turbulence.

Function of a Tube Bundle

The primary function of a tube bundle is to facilitate heat transfer between two fluids. Here’s a detailed look at how this works:

-

Heat Exchange: One fluid flows through the tubes (tube-side fluid), while another fluid flows around the tubes (shell-side fluid). Heat is transferred from the hotter fluid to the cooler fluid through the walls of the tubes.

-

Temperature Regulation: Tube bundles help in regulating temperatures in various systems by either heating or cooling fluids. For instance, in a cooling system, hot fluid is cooled as it flows through the tubes, while a coolant circulates around the tubes.

-

Pressure Management: Tube bundles are designed to handle high pressure and temperature differentials, ensuring that fluids are processed efficiently without compromising safety.

Design Considerations

The design of a tube bundle is crucial for its performance and efficiency. Key considerations include:

-

Tube Configuration: The arrangement of tubes affects heat transfer efficiency. Common configurations include:

- Inline: Tubes are arranged in a straight line. This is simple and often used for lower flow rates.

- Staggered: Tubes are offset in a grid pattern. This design promotes higher heat transfer rates due to increased turbulence.

-

Material Selection: Tubes and shells are made from various materials, such as stainless steel, copper, or titanium, depending on the operating conditions and the fluids involved. Material selection affects durability, corrosion resistance, and heat transfer efficiency.

-

Flow Arrangement: The flow arrangement, whether counterflow, parallel flow, or crossflow, impacts the effectiveness of heat exchange. Counterflow arrangements, where fluids flow in opposite directions, are typically the most efficient.

-

Size and Capacity: The dimensions and capacity of a tube bundle must be matched to the requirements of the system, including the volume of fluid, temperature ranges, and pressure conditions.

Industry Applications

Tube bundles are versatile and find applications across various industries:

-

Power Generation: In power plants, tube bundles are used in condensers to cool steam and in heat exchangers to transfer heat between fluids.

-

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, tube bundles are crucial for heat exchangers that manage indoor climate control.

-

Chemical Processing: Tube bundles in chemical processing plants are used for heat transfer in reactors and other equipment, handling aggressive chemicals and high temperatures.

-

Petrochemical Industry: Tube bundles play a role in refining processes, including distillation and heat exchange in various petrochemical applications.

-

Marine Applications: In marine engineering, tube bundles are used in shipboard cooling systems, including in the cooling of engine systems and other machinery.

-

Food and Beverage Industry: Tube bundles are employed in heat exchangers for pasteurization, cooling, and other temperature-controlled processes.

Maintenance and Longevity

To ensure the efficient operation of tube bundles, regular maintenance is essential. Key maintenance activities include:

-

Inspection: Regular checks for corrosion, fouling, or any damage to tubes and shell components.

-

Cleaning: Periodic cleaning to remove deposits and maintain heat transfer efficiency.

-

Replacement: Replacing worn or damaged tubes or components to avoid system failures and maintain performance.

Conclusion

Tube bundles are integral to many industrial processes, providing efficient heat transfer in various applications. Their design, material, and configuration play significant roles in their effectiveness and suitability for specific tasks. By understanding their function and applications, industries can better leverage tube bundles to optimize system performance and operational efficiency. For any specific requirements or detailed design considerations, consulting with experts in the field can provide tailored solutions that meet your needs.